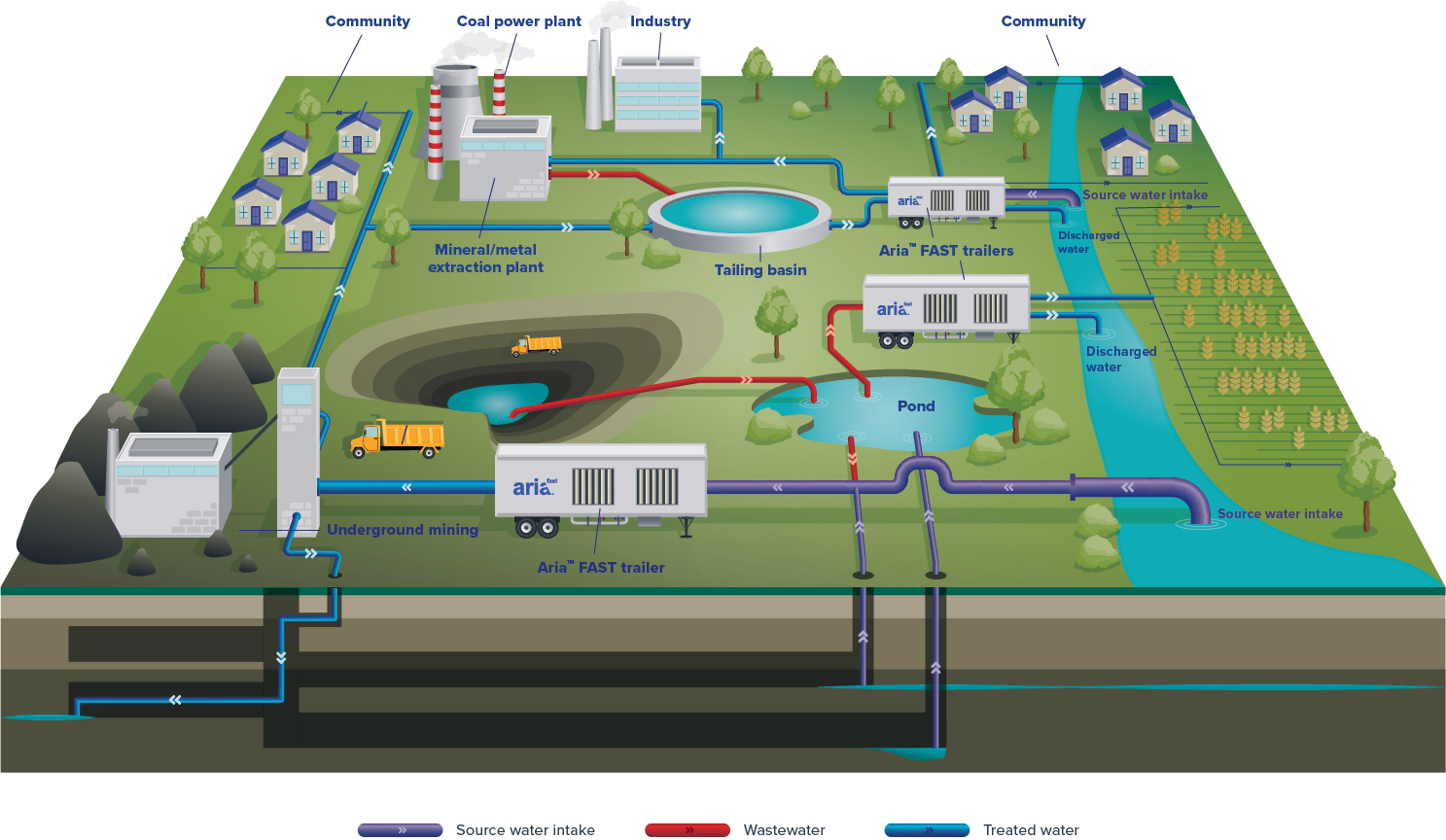

Water supply and scarcity, combined with regulatory constraints, are changing the landscape of mine site water management. Because mining operations use a tremendous amount of water, it’s important that you meet current and future environmental requirements when treating raw water and maintaining high-quality water standards. Whether water reuse or wastewater management is your goal, Aria Filtra™ offers a variety of solutions designed to meet your needs. Contact us today for more information about our mine water solutions.

Aria Filtra assists mining companies with:

• Rapidly treating excess water for reuse

• Meeting stringent discharge requirements

• Allowing for the proper release of water

• Improving water usage

• Treating pit and pond water

• Removing high solids and particulates via membrane filtration

• Reducing dependence on external water supplies

Contact Us

Aria Filtra delivers trusted proven water filtration solutions that solve your toughest water treatment challenges.

Water on demand, when and where you need it

Whether you require water treatment for short-term, long-term, or emergency relief, the Aria FAST mobile water solution provides a complete, automated membrane system. Aria FAST requires minimal labor and can be operational within hours of arrival on site.

Fits your schedule, your footprint, and your budget

Packaged water solutions offer pre-engineered systems with trusted microfiltration (MF) and ultrafiltration (UF) technology. The modular, skid-based designs can be configured to fit any footprint, making this technology ideal for facilities with limited space or small capacity needs.

Intelligent, maximum performance reverse osmosis

IMPRO systems deliver CCRO technology in mobile-ready containers or packaged skid-mounted systems. The IMPRO is designed to fit your groundwater treatment and water polishing needs.

Go behind the scenes of some complex water challenges with our client success stories.

A high-altitude gold mining plant in Peru required a quick, reliable wastewater solution to meet peak demand in the summer months, treat the mine leachate, and prevent the existing RO membrane from collapsing or releasing contaminated water into the environment. Aria Filtra delivered a fast, easy-to-operate solution that fit into the plant's small footprint.

Following its purchase by Avino Silver & Gold Mines, the Bralorne Gold Mine required construction to get back online. The mine needed a faster, more affordable, and reliable treatment solution than its existing media filtration system. Aria FAST mobile water treatment was selected because it could handle construction challenges, remove contaminants, and protect local waters.

An operating mine in remote Nevada experienced a pit flood as a result of groundwater recharge. More than 40 million gallons of water flooded the open pit, bringing mine operations to a halt. The groundwater, when introduced to the pit, was then contaminated with high levels of numerous contaminants such as manganese, heavy metals, and sulfides. An immediate, robust solution was needed to resume mine operations.

Minera San Xavier, a subsidiary of New Gold Inc., has a gold mine that was closed and in reclamation near San Luis Potosi, Mexico. To enable the mining operation to produce permeate for leach pad rinsing, eliminating salts from the process solution and avoiding the use of well water in compliance with Mexican regulations, the company selected Aria Filtra and ChemTreat Mexico to provide a mobile temporary deployment of microfiltration and high-recovery reverse osmosis.

Our service and support team has deep water quality, process optimization, and technical expertise.

The global Aria CARE service team is available to support you with the operation and longevity of your Aria Filtra membrane systems and filtration solutions. Our services include annual maintenance, health checks, 24/7 technical phone support, and much more.

Real-Time System Monitoring with Aria SMARTBOX™

Gain insight into how your system is operating today and how it will perform in the future. Our Aria SMARTBOX solution provides secure and private remote monitoring that offers quick and reliable access to your system’s performance anytime, anywhere, on any device.

We’re here to provide long-lasting, reliable filtration solutions that meet your water and wastewater treatment needs.

The functionality on this page was blocked due to your browser’s security settings, or the server is unavailable. Please try using a different browser to access this page or change your browser security settings.

For further assistance, please contact Aria Filtra at +1 (866) 475-0115

Aria Filtra, a division of Trojan Technologies and the Water Quality Segment, is the filtration partner of choice for companies who need smart water solutions. With more than two billion gallons of installed capacity spanning six continents, we are a leader in membrane-based water treatment solutions. Our broad portfolio of intelligent, reliable water systems and modules are used by leading industrial and municipal customers to ensure the continual supply of safe and reliable water.

© Copyright Aria Filtra | 839 NY State Route-13, Cortland, NY 13045, USA | +1-866-475-0115 | Fax +1-607-758-4526